(Published on Lift-Truck Technology International – 2017, page 66-67)

ADVANCED HYDRAULIC SOLUTIONS OFFER NUMEROUS BENEFITS FOR MANUFACTURERS OF LIFT TRUCKS

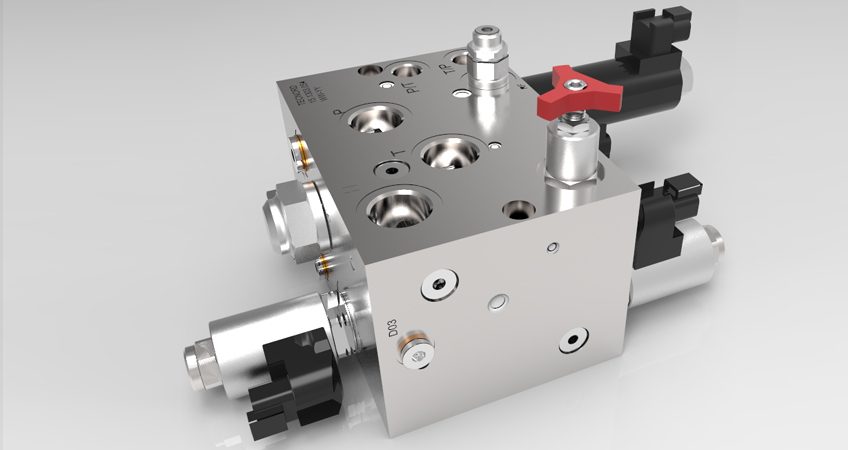

In the lift-truck industry, split systems are known and respected. For those working in this area, the system represents the perfect blend of different models of proportional valves designed to meet the most testing of performance requirements placed on the machines. This well-proven hydraulic solution and components that comprise it are the synthesis of the most advanced technology adopted by Tecnord, formed over many years of consistent dedication to forklift applications. The components that make up the split system are the main lift and the lower block, including the proportional raising/lowering of the mast cylinder and the proportional meter-in flow control of the auxiliary functions, the selector valves for side-shift function, and the selector valve and single/dual counterbalance valves for reach and tilt functions.

Split system strengths

The benefits of the system include:

• The unique split hydraulic circuitry configuration with individual directional control valves are separated from the inlet manifold and interconnected through a dual hydraulic ‘feed and return bus line’, making the system similar to an electronic CANbus setup, where a number of wires connecting the various elements is reduced to only two wires.

• Energy saving by working in a load-sensing mode, allowing pressure-compensated simultaneous operation of lift and one of the three auxiliary functions.

• It is a compact and easily installed solution that can be customized for different types of machine.

• Cost-effectiveness through a combination of high production components of outstanding performance and proven reliability.

Tecnord proportional valves in the system are the EU F2A-size 12 – a two-way proportional flow regulator with built-in pressure compensator for no leakages in the lowering function; the EG S4M-size 10 – a four-way/three positions directional/proportional valve for fl ow control up to 27 l/min and an EU P3A-size 12 – a three-way/two-position directional valve for mast raise control.

Chinese interest

This system has been recently adopted by a large manufacturer of electrical forklift trucks in China, where Tecnord has been directly involved since 2014 through Delta PowerTech Ltd, a company-owned 2,500m2 production unit in the Beijing area for the manufacture of electrohydraulic and electronic components and for the provision of the same high quality services to customers in the Asia-Pacifi c region as are provided from the other Tecnord locations in Europe, North America and Brazil. In addition to the hydraulic components and hydraulic integrated circuit manifolds, Tecnord also offers a complete range of electronic drivers for the appropriate control of proportional cartridge valves such as single or multiple pulse width modulation drivers and machine management system controllers incorporating fi rmware written by Tecnord engineers to fulfi ll all machine operating functions.